Reading the ingredients list of an industrially-produced sausage can be daunting. We’ve been trained to mistrust “scientific sounding” ingredients, and there are ongoing discussions about the health risks associated with many common additives. I don’t wade into that debate too much in this post, partly because I know so little about it, but also because there are few reliable studies on the subject. The fields of nutrition and health are so tied up with industry that it’s hard to know what to believe. I’ll leave it for you to decide what ingredients are okay and which are not. In this post I simply describe the role the additive plays in the sausage-making process. Interestingly, most them are used to accelerate the mixing and curing phases and increase production. They are therefore useless in a leisurely home setting. That’s the best part about making sausages at home: you decide what goes in them.

Reading the ingredients list of an industrially-produced sausage can be daunting. We’ve been trained to mistrust “scientific sounding” ingredients, and there are ongoing discussions about the health risks associated with many common additives. I don’t wade into that debate too much in this post, partly because I know so little about it, but also because there are few reliable studies on the subject. The fields of nutrition and health are so tied up with industry that it’s hard to know what to believe. I’ll leave it for you to decide what ingredients are okay and which are not. In this post I simply describe the role the additive plays in the sausage-making process. Interestingly, most them are used to accelerate the mixing and curing phases and increase production. They are therefore useless in a leisurely home setting. That’s the best part about making sausages at home: you decide what goes in them.

I define “additive” as any ingredient added to the sausage besides meat and fat. Most of the following info, and all the bits in quotation marks, are from Processed Meats.[1]

Water and Ice. Unlike with commercial bacon and hams, which are injected with water to increase yields, water is an integral part of sausage-making and is usually the first ingredient listed after the meat. Water and ice cool the meat, counteracting any frictional heat that develops during mixing and allowing the meat to be mixed longer and develop more texture. Water also helps dissolve salt, “imparts fluidity to the emulsion”, and improves the mouthfeel of the final sausage by adding moisture.

Salt (ie. table salt, sodium chloride) is the most important additive. Actually it is indispensable. It prevents microbial growth, “aids in solubilizing myosin-type proteins”, “increases water-holding capacity”, and of course makes for better flavour.

Curing Salts (sodium nitrite, sodium nitrate, potassium nitrate, and others) perform several functions in sausage-making. For instance:

- They form nitric oxide, which interacts with myoglobin to develop the rosy pink colour we expect in cured meats.

- The nitric oxide also prevents fat rancidity by binding to iron atoms, which otherwise would oxidize the fat.

- Curings salts give the meat a distinct, piquant flavour.

- They also prevent the growth of pathogenic microbes.

Curings salts are much maligned in the media. When nitrite interacts with amino acids in the meat, nitrosamines form. These are known carcinogens. However, curing salts are absolutely essential for traditional air-dried sausage like salami, preventing the growth of deadly botulism bacteria. I use sodium nitrite in many of the sausages I make at home, and all of the sausages I make at work. For more on curing salts and their role in charcuterie, see this post.

Ascorbates and Erythorbates. Ascorbates and isoascorbates (also known as erythorbates) are “closely related” and used interchangeably. They are “active reducing agents [that] react with nitrite increasing the yield of nitric oxide”. They “ensure development of desired color in cured meats” and “speed up the curing reaction and prevent formation of secondary N-nitrosamines”.

Sugar (common forms including sucrose, dextrose, and corn syrup) is added chiefly for flavour. In the case of fermented sausages like salami, it is added to feed lactobacteria, which convert the sugar to lactic acid and give the final sausage its characteristic tanginess.

Phosphates. There are two types of phosphates used in processed meats: acid and alkaline. Sodium acid pyrophosphate is a cure accelerator. It “accelerates [the] development of cured color in rapid processing of bacon, frankfurters, or bologna by lowering the pH rapidly by about 0.2-0.3 units during initial stages of the operation”. Alkaline phosphates (the most common examples being sodium tripolyphosphate, sodium hexametaphosphate, and tetrasodium pyrophosphate) “increase water-binding capacity [by] acting as polyelectrolytes to increase ionic strength”. “This frees some of the negatively charged sites on the proteins so they can bind more water”. Alkaline phosphates also “increase fat emulsifying capacity of the myofibrillar proteins” by “solubilizing and dissociating actomyosin into actin and myosin, which in their dissociated forms can emulsify more fat”.

Glucono-δ-Lactone (that middle character is a lower-case Greek delta, so this additive is often called GDL) is also a “cure accelerator [that] speeds up development of cured meat color”. It “will reduce the pH of the batter by about 0.2-0.3 units, which accelerates the conversion of the meat pigments to their desirable forms. It is valuable during rapid processing.”

Acid Sprays are used prior to smoking meat, which makes me think that it improves smoke adherence, though I’ve never come across this explanation in the literature. An acid spray reduces the surface pH and “either coagulates proteins at the surface or permits coagulation at a lower temperature”, which “helps development of surface color”.

Binders and Extenders perform one or several of the following functions:

- reduce formulation costs (ie. by bulking up the sausage with a product that is cheaper than meat)

- improve cooking yield

- improve slicing characteristics

- improve flavour

- increase protein content

- improve emulsion stability

- improve fat binding

- increase water binding

Some examples of binders and extenders:

Soy Protein Extenders are combined with flavouring agents, binders (like egg albumen) and fat to make “meat analogs”, which is a disgusting phrase. They also increase the water and fat binding characteristics of the batter.

Milk Protein Extenders are used because “milk proteins are more heat stable than meat proteins. Thus, they help to stabilize meat emulsions that are chopped at high temperatures”. They are more common in fine-textured sausages like bologna or weisswurst.

Flours and Starch are both binders and extenders. They “absorb large amounts of water and … become sticky, causing the ground up meat particles to adhere to each other”. While extenders are generally maligned by foodies, flavourful starches like toasted bread crumbs can be a fantastic source of flavour in sausages. Heston Blumenthal considers toasted wheat rusk an indispensable component of classic English bangers. I consider toasted bread crumbs an indispensable component of meatballs.

Colloids and Gums such as carageenans and alginates are sometimes used to bind low fat products. But why would you buy a low fat sausage in the first place?

Flavour Enhancders including MSG, IMP, and GMP are sometimes used to bolster the flavour of the meat. MSG was demonized in the early ’90s as the cause of mysterious symptoms that manifested themselves after the consumption of Chinese food. For an eye-opening discussion of the MSG scare, see Jeffrey Steingarten’s essay “Why Doesn’t Everyone in China Have a Headache?”, part of a collection entitled It Must’ve Been Something I Ate.

Two Case Studies

To give you some real-life examples, I walked through the deli section of a Superstore and wrote down the ingredients list of a couple items.

Johnsonville Original Breakfast Sausages. The ingredients list: pork, water, corn syrup, dextrose, lemon juice powder (maltodextrin, lemon juice solids), monosodium glutamate, flavours, calcium stearate, silicon dioxide.

So. Here we have a fresh sausage, ie. raw meat stuffed into casings. The use of curing salt is optional in this case, and we can see that there is no sodium nitrite. Usually acids are used as cure accelerators, but since there’s no curing salt in these sausages, the lemon juice powder must be for flavour. There are several sweeteners: corn syrup, dextrose, and potentially maltodextrin. This sausage contains MSG to boost the meaty flavour.

Calcium stearate is often used as a lubricant. I’ve found some admittedly sketchy sources online that suggest sausage casings can be coated with calcium stearate to let the sausages slide over each other without sticking and tearing.

I’m only familiar with silicon dioxide as an anti-caking agent, and with a number of powdered ingredients (dextrose, lemon juice powder, MSG) I assume that’s what it’s being used for here. Just speculation, though.

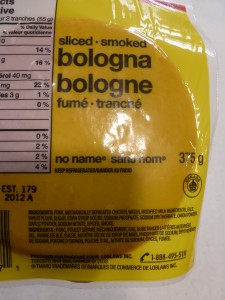

No Name Sliced Bologna. The ingredients are as follows: pork, mechanically separated chicken, water, modified milk ingredients, salt, wheat flour, sugar, corn syrup solids, sodium phosphate, sodium erythorbate, onion powder, garlic powder, sodium nitrite, spices, smoke.

Bologna is a North American bastardization of mortadella. It is a very fine-textured sausage, meaning that the meat and fat have been ground and processed, emulsified into a uniform paste. Since the meat and fat are being chopped, ground, processed, and mixed, there is a lot of potential for friction that will heat the batter and break the emulsion. After pork and chicken, the main ingredient here is water, which would be added to the meat extremely cold, possibly even frozen, to keep the temperature of the batter down. Milk proteins in the form of “modified milk ingredients” are used because they are more heat-stable than meat proteins. The wheat flour also acts as an emulsion stabilizer.

Bologna always contains curing salt (sodium nitrite in this case) to develop the characteristic pink colour. As this is a mass-produced product, we therefore have a couple curing accelerators: sodium phosphate and sodium erythorbate. All other ingredients are for flavour, though I have to say that “mechanically separated chicken” has always sounded gross to me. It should be noted that most of the flavour enhancers are heavily processed: corn syrup solids, onion powder, garlic powder.

Reference

Pearson, A.M., and Gillett, Tedford A. Processed Meats. © 1999 Aspen Publishers Inc., New York. This was a very interesting read. In fact, I hope to have similar posts on commercial bacon and ham, which will elucidate why they are so, so much worse than their homemade counterparts.